Manufacturing and installation of equipment maintenance platforms in Kazakhstan

| Service name | Service cost |

|---|---|

| Инженерные услуги | по запросу |

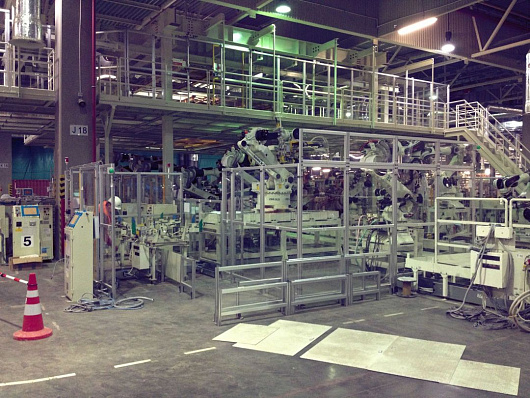

All platforms can be categorized into types such as:

- mobile platforms: lightweight platforms for crossing over pipelines, ventilation systems or production lines,

- platforms for maintenance of process equipment: stationary structures on racks for repair and operation,

- platforms for maintenance of production vessels: for safe piping and service water filling/discharge.

Design of Equipment Maintenance Platforms

When designing platforms, it is necessary to be guided by the requirements of GOSTs and SNiPs, as well as to take into account the recommendations of the safety engineer regarding the material of platforms and their coating. Every platform must offer secure access to electrical and mechanical equipment.Service platform structures should be able to support the loads that are applied during installation, transportation, and use.

When choosing a material for the manufacture of service platforms, designers rely on the following data:

- Temperature conditions

- Humidity level

- Features of products and raw materials, the existence of alkalis and acids

For the safety of the personnel who will maintain the equipment during its operation, all of these considerations must be made at the design phase.

Fabrication of Equipment Maintenance Platforms

Manufacturing components for their subsequent final assembly at the operating site is the initial step in the fabrication of service platforms. For service platforms, ladders, and fences to be long-lasting and, most importantly, safe for workers, the right material must be chosen during manufacture.Temperature, humidity, and the type of contaminants are among the environmental factors that are considered during the design phase.Before being shipped to the installation site, sections of metal constructions are accepted by the technical inspection. Subsequently, a second examination is conducted on the site.

They are put together on location following the facility's final approval of every component. Surveyors use specialized equipment to designate the area for this purpose. The welding process is the next major step in building the service platforms. Specialists are governed by the designated welding process, material, and equipment when performing welding operations. Every welding professional needs to be certified and have the required credentials.

Setting up Platforms for Equipment Maintenance

A skilled staff and the availability of top-notch, contemporary tools are both necessary for the efficient and proficient installation of equipment maintenance platforms..

The process of erecting metal structures on the job site starts once the modules and components of platforms and ladders have been designed and manufactured.

Metal structure installation works can be divided into the following main stages:

- Incoming quality control of elements received at the facility;

- Marking on the site;

- Installation of load-bearing beams and posts;

- Installation of floors, ladders and the service platforms themselves;

- Quality control and tests;

- Delivery to the customer.

Cost of Fabrication of Equipment Maintenance Platforms

The materials and types of equipment maintenance platforms as well as the complexity of the work that will be involved determine the cost of manufacture.As standard, the cost of fabrication of the platforms includes:

- Design work

- Manufacture of elements of platforms

- Assembly of platforms at the customer’s site

- Painting, finalization and delivery of the project

Please complete the form below, and we will get in touch with you to determine the cost of fabricating an equipment maintenance platform.